If you are considering buying a Pocock Racing Shell for the first time, here are some things to consider.

1. We don’t want to build the most boats, we want to build the best boats.

We could crank boats out of an assembly line like widgets. But that’s not us. We are about quality and craftsmanship. Our guys in the shop take their work personally, and the result is quality that will stand up to or surpass any other shell in the world.

2. Providing superficial customer service doesn’t add any value. Being there when it counts does.

Just because a boat builder is at every regatta doesn’t mean they are providing good service. It does mean they are spending a lot of money travel instead of on R&D. Our service is personal. When you call, a person answers the phone. If there’s a problem, we fix it. If you have a question or comment about the boat, or just want to talk rowing, give us a call. That is what we think it means to be your boat builder.

3. Warranties are great, but how about a boat and parts that don’t break in the first place.

Isn’t the best warranty one that you never need to use? Pocock boats just don’t break. And with minimal attention and maintenance, the parts don’t either. Don’t believe us? See what our customers are saying.

4. No boat builder is using special materials, but that doesn’t mean all boats are created equal.

There’s no shortage of marketing going around in the rowing world. But here’s a fact: we all use the same materials. There’s no such thing as a special skin or finish on a boat. What is different is how materials are put together, and where material is used.

Every boat builder approaches the FISA minimum weight standards differently. Our processes and layup schedule have been carefully honed over the years, and are executed by our master craftsmen. We believe that our people, processes and proprietary layup schedule yield the fastest and most durable boats in the world.

5. Pick up a 1-gallon can of paint. That’s dead weight you won’t find on a Pocock.

Customers always ask why we only paint our boats white. The truth is, we don’t paint them in the traditional sense at all. The white of your boat is part of the hull. It is applied directly to the mold and then the boat is built on top of it. It is actually the very first step of the process. When the boat comes out of the mold, it’s already shiny white. Besides making the hull extremely durable, it eliminates the need for a primer layer.

While you may have the option to get your school colors, you’re also getting upwards of 10 extra pounds of paint. If you look under layers of custom paint and primer, you will find a good amount of Bondo. None of these materials are enhancing the speed or durability of your shell.

Finally, you are going to take a hit to your resale value with a custom painted boat. It is a fact that white boats retain their value and sell more quickly than custom painted shells.

6. Who do you want to design your boat, a rower or a sailor? Pocock engineers know racing shells.

There are incomparable differences between a racing yacht and a racing shell. What allure is there to an America’s Cup architect building your rowing boat? Our designers know about racing shells, the hydrodynamics of a rowing hull, and the difference between wind-generated boat speed and human-generated boat speed. It’s a different beast.

7. Pre-Preg Carbon is a shortcut. That’s why you won’t find it in any Pocock boat.

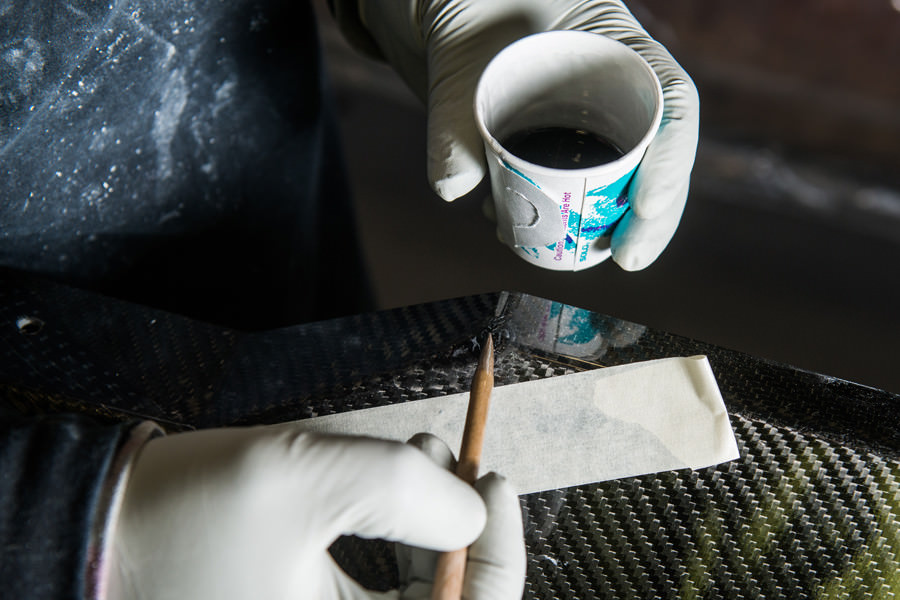

Carbon fiber alone isn’t stiff – it is simply woven sheets that come on rolls just like any other fabric. To become the stiff material that makes up a boat, resin is applied to the carbon fiber in a specific proportion. When building a boat, this application happens in one of two ways:

- Wet-Layup: the resin is hand-applied to the carbon once it’s draped in the mold.

- Pre-Preg: carbon comes with the resin already on it (or “pre-impregnated”).

Pre-preg is a one-size-fits-all method. It’s good for fast production with little skill required, but the results are far less precise.

Our boat builders are precision craftsmen, and they have the skills required to employ the significantly more sophisticated wet-layup method. We chose to build our boats this way because it means that your shell will be more durable and last longer. Pococks, along with the European brands, are the only boats made this way.

8. “Made in China” carries a stigma for a reason. Pocock Shells are proudly made in America.

Cheap Chinese products are everywhere these days. We’d just prefer to keep them out of the boathouse. Our boats are made from start to finish by a team of skilled craftsmen in our Everett, Washington shop. We make all our own machined metal parts, all the carbon fiber parts, fins, rudders, our boat trailers, and the boats themselves in our shop.

For the parts we can’t make in house, we work with local craftsmen, or other partners nationwide. We are a proud American company, and we consciously choose to work with other American companies and craftsmen.

9. Efficient and easy parts ordering.

Since Pocock is based on the West Coast, when you knock a fin off at afternoon practice and call us that night to order a new one, we’re still open and ready to ship it to you in time for tomorrow’s row. Really! If you loose a fin in Connecticut at 3pm on a Thursday, we can get you a new one by Friday at 8am. The only way for another manufacturer to deliver this level of service is for you to drive to their shop yourself!

10. We’re not your father’s (or grandfather’s) Pocock. But we learned an awful lot from them.

In an industry where other boat builders have trended towards building more boats, faster and cheaper, we seek to maintain the culture of excellence set forth by our founders. There are plenty of vintage Pococks still getting pulled off the racks for practice, and innumerable others hanging from rafters in restaurants and boathouses whose sleek beauty is a testament across the years of the company values set forth by George and Stanley.

Today, the composite boats we are building couldn’t be more different from those built by George and Stanley. The materials, technology, and engineering of racing shells in the 21st century, and the sport itself, have changed. What remains is a deep love for the sport, and a pursuit of excellence in everything we do.